In the ever-evolving world of printing and graphic arts, the quest for outstanding visual appeal and durable protection of printed materials has led to the innovation of UV coating machines. These cutting-edge devices have revolutionized print finishing processes, providing a range of benefits that elevate the quality and longevity of printed products. In this article, we will delve into the fascinating world of UV coating machines, exploring their functionalities, advantages, and the transformative impact they have on the print industry.

What is a UV Coating Machine?

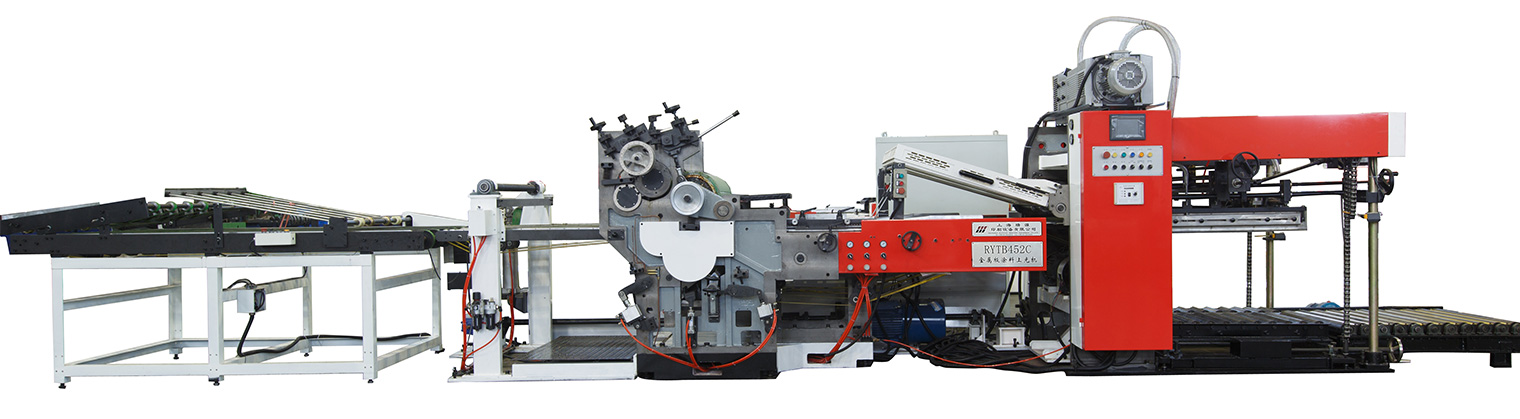

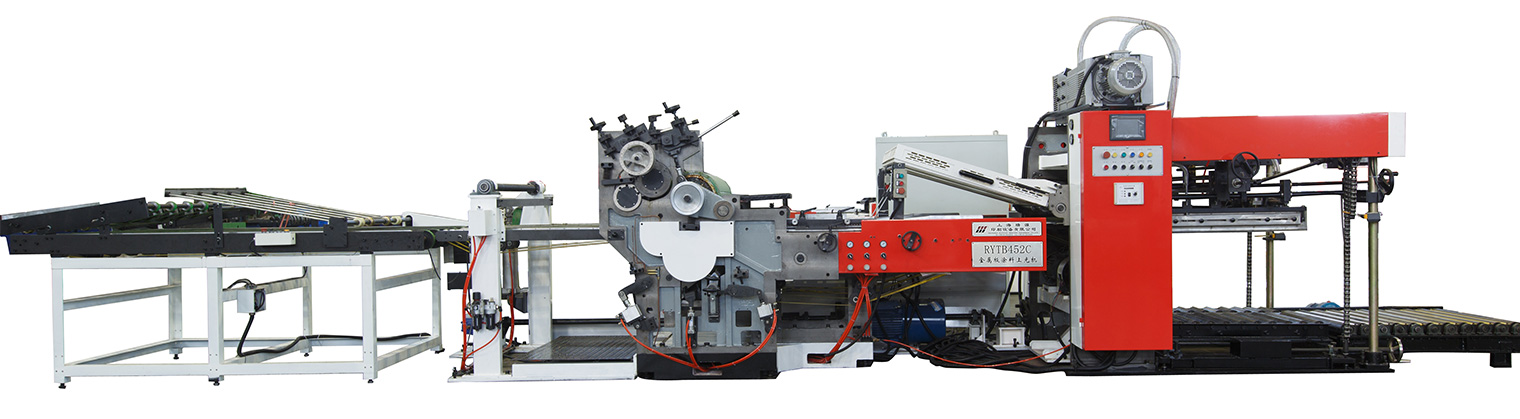

A UV coating machine is a specialized device used in print finishing processes to apply a thin layer of ultraviolet (UV) cured coating onto printed materials. The UV coating is a liquid polymer that solidifies when exposed to UV light, creating a glossy, scratch-resistant, and vibrant finish on various substrates, such as paper, cardboard, and synthetic materials. UV coating machines come in various configurations, ranging from tabletop models for small-scale applications to high-speed industrial units for large print runs.

Advantages of UV Coating Machine

Enhanced Visual Appeal: UV coatings impart a stunning glossy finish that enhances the vibrancy and depth of printed colors. This premium look adds a touch of elegance to products like brochures, catalogs, packaging, and promotional materials, elevating their overall aesthetic appeal.

Increased Durability: UV-coated materials benefit from increased durability, making them more resistant to scratches, scuffs, and fading. This protective layer shields printed items from moisture and environmental factors, ensuring that they maintain their pristine appearance for an extended period.

Quick Drying and Curing: Unlike traditional coatings that require time to dry, UV coatings cure instantly when exposed to UV light. This rapid curing process significantly speeds up production times, allowing for faster turnaround and reduced lead times.

Eco-Friendly Solution: UV coatings are solvent-free, which means they do not emit volatile organic compounds (VOCs) during the curing process. As a result, UV coating machines offer an eco-friendly alternative to traditional solvent-based coatings, promoting sustainable print finishing practices.

Transforming Print Finishing Processes

The integration of UV coating machines into print finishing processes has transformed the industry in various ways:

Versatility: UV coatings can be applied selectively to specific areas of a print, creating striking spot gloss effects and matte contrast. This versatility opens up a world of creative possibilities, allowing designers to experiment with textures and visual elements.

Improved Resistance: The added protection provided by UV coatings makes printed materials more durable, extending their shelf life and reducing the need for reprints. This translates to cost savings for print service providers and end-users alike.

Enhanced Branding: The high-quality finish achieved through UV coating imparts a premium feel to printed materials, reinforcing brand identity and leaving a lasting impression on customers.

RUNYUAN uv coating machines are green environmental protection to achieve 0 VOCs emissions.

UV coating machine for sale at suitable prices. Cost-saving 20-30% of metal decorating printing and no request for the Auxiliary Equipment.

As one of the professional uv coating machine suppliers, our uv coating printing machines have good leveling outlook and high fullness.

English

English français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe فارسی

فارسی magyar

magyar Ελλάδα

Ελλάδα Burmese

Burmese